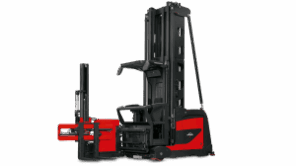

Very Narrow Aisle Trucks

HIGH HANDLING PERFORMANCE IN NARROW AISLES

Very Narrow Aisle Trucks: Ideal for Storage

Whether you refer to it as a narrow aisle forklift, a VNA truck, a truck for a very narrow aisle or a turret truck, Linde has it.

Contrary to popular belief, a warehouse does not mean that is an endless storage space available. It simply means everyone must get creative with how the space is used effectively. This can be tricky as inventory may grow beyond the capacity of the warehouse. To keep the area functional, going higher may be the most effective way to add space, but it may also mean stacking shelves closer together. The problem with this is narrow aisles may make moving around tougher and less workable. That is unless there is special equipment around that can still make use of that space.

Linde understands the challenges warehouse owners and supervisors face. To help, they have designed forklifts that can venture down even very narrow aisles.

Why Choose Narrow Aisle Forklifts?

Think about a traditional forklift. They often have a cab for the operator to sit in and forks that stick straight out in front of the machine. To use them, the operator must get the right angle when picking up pallets. This means jockeying into a position where the operator can then slide the forks forward. It is the only viable way to get under whatever is being picked up. Then, before setting it on a platform or a shelf, the realigning process must take place again in that new area.

All these different steps and manoeuvres take time and ample space for an operator to be able to do it. Who has the time or the space in today’s busy, crowded world?

Forklifts that are designed for small, narrow aisles are designed differently. Their forks are often on the side so all the operator has to do is pull up beside the shelves that they need. From this side position, they can lift inventory or place it on a shelf, even one that is high up.

The aisle only has to be wide enough for these smaller forklifts to get through. The fact that twisting and turning to get the proper angle can be avoided will speed up loading and unloading times. It will help to make everything in the warehouse run more efficiently. As a result, it will also increase productivity.

Another bonus for having these easier-to-operate forklifts is that there will be a noticeable decrease in inventory damage because of misplaced forks. Fewer pallets will be dropped, fewer boxes will get poked by misplaced forks, and ultimately everyone in the warehouse will have fewer mishaps.

Narrow Aisle Forklifts Increase Small Space Productivity

It can be a real challenge for any equipment operator to navigate small aisles and high shelves. Therefore, many narrow aisle forklifts are fully equipped with navigation systems. These systems ensure that the driver or operator knows exactly where they need to be within the warehouse. They can see where they are, where they need to be, and how to get there in the most efficient way possible.

When equipment operators need to lift the forks to reach high shelves, they can have help. They can know that they have good positioning to pick up or set down the stuff they are moving. This comes from camera systems that are placed carefully to give them a good view from the floor. A press of a button is all it will take from there because some forklifts are equipped with automatic cycles that ensure it goes smoothly.

A forklift that is designed for higher racks will also help to get the job done. Some lifts can move easily around any warehouse setup. Some may even be able to lift while moving to further keep everything running in the most efficient way possible.

VNA Trucks Operate Safely in All Areas

Another aspect of VNA (Very Narrow Aisle) Trucks is that they make even the smallest areas safer to work in for warehouse team members. There is a control system onboard that regulates all aspects of the forklift operation from driving speed to lifting speeds. It is dependent on the weight of the load and can make it easier to stop quickly if necessary.

However, this will never slow down the processes that are required for team members to get done, even if someone is hauling a very heavy load. When using a turret truck or some other type of picking forklift, there are options. There are features on board that ensure it will move around the warehouse efficiently from one place to another. The job gets done while allowing operators to avoid dangers, no matter how high the pallets are stacked. Everyone can worry less even if the high stacks lessen the visibility of what may be lying ahead.

Depending on the challenges inventory may cause in the warehouse, some extra features can be added to the VNA truck. These extras include Aisle Safety Assistants, which can help drivers stay safe on uneven areas, prevent lifts if there are obstacles or supports in its path, and switches that will allow operators to always keep their hands on the controls.

The Right Turret Truck is Available

There is a narrow aisle forklift available to meet every need for equipment operators in any warehouse. As proof, custom orders can be made based on the space available in the warehouse, the type of inventory being handled, and the skill levels of equipment operators.

There is a wide range of customisation options that include:

- Increasing Or Decreasing the Lift Capacity. There are a variety of lift capacity options available to meet the high demands of warehouses in today’s world.

- Improving How Well They Handle. We know that the well-being of team members is important. These machines are easy to operate and they can overcome specific challenges such as uneven flooring or outdoor spaces, through improved handling.

- Batteries That Will Last Throughout Longer Periods Between Charges. When speed and efficiency matter, our equipment can keep up. These lifts are designed to go the distance and not stop until equipment operators are ready to call it a day.

- Increased Lift Height If Needed. Not all warehouses are created equal. Why should all lifts work the same as others? There are various lift heights available to meet the demands of warehouses both large and small, making it possible for inventory to stack higher than ever before.

No one wants to have to work hard to get their job done, yet older style lifts have often been called uncomfortable to use. We have turret trucks that allow freedom of movement and ease of control so that operators can stay more alert while getting the job done. Some have two control panel options including a front control panel for easier pallet handling. They may have regenerative braking, spring-loaded parking/emergency brakes, enclosed cabins for blocking draft and wind, and more. All this is topped off by a comfortable seat that gives operators easy access to everything they need to be able to use to get their job done.

Warehouses should work the way we want them to. The storage space available shouldn’t hold anyone back. We also feel that inventory deserves to be transported in the safest way possible. Loading up or shipping out, shouldn’t mean complications for anyone in the warehouse. It should simply run effectively and efficiently, no matter how busy the warehouse may sometimes become.

Our goal is to help. We want to make warehouses as productive as possible based on what is needed the most. We are available to answer questions and guide everyone on how to find a VNA truck that can meet the needs of any warehouse or situation.

Discover How Practical Very Narrow Aisle Forklifts Are

The days are gone when warehouses could only have a couple of forklifts. Today’s world may require several forklifts, lift trucks, etc. operating at one time.

The VNA forklifts that are available for warehouses today are not just cost-effective to bring in, but they are also practical to have. They do not require daily maintenance. Warehouse operators can expect them to operate reliably.

Some equipment is also available for testing if the owners and operators are trying to discover practical solutions. Equipment rentals, both singles and fleet options are available. We offer all types including:

- Pallet Trucks

- Reach Trucks

- Order Pickers

- Tow Tractors

- Automation Equipment

and much more.

To ensure that warehouses run smoothly and efficiently, we provide equipment options to make the day-to-day processes easier for everyone. We offer rentals to do our part to ensure that solutions are found by any warehouse or company that may need them.

At Linde Singapore, we have the right lift for virtually every situation within the warehouse. We are a global company that can meet the needs of today’s busy world. If we cannot find what is needed in our Singapore location, we can reach out to ensure that every warehouse gets what is needed for their specific needs. As further proof of our dedication, if troubles do come up for our equipment, such as accidents or breakage, we will do our part to get it back up and running in the fastest way possible because we are a company that stands behind what we have to offer.